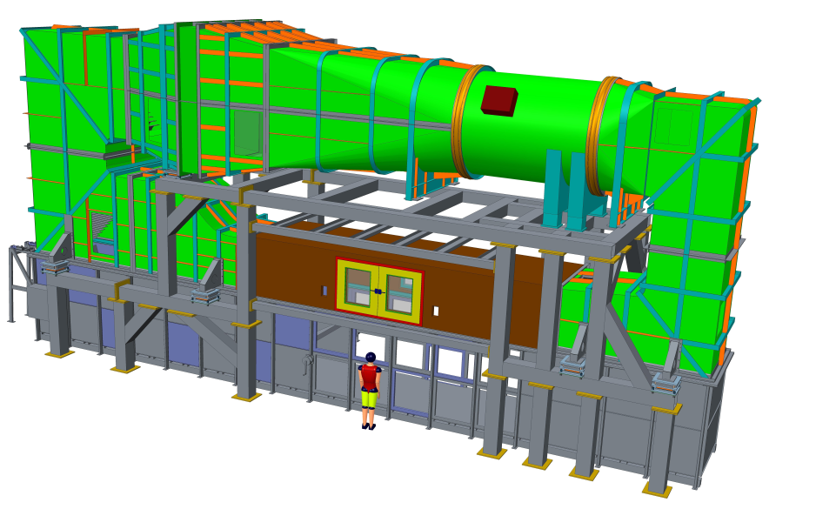

Icing Wind Tunnel Over Wave Basin

Purpose

- Simulate variety of harsh ocean environment conditions: cold temperatures, high winds, and precipitation that is repeatable and controlled.

- Marine Icing and Atmospheric Icing.

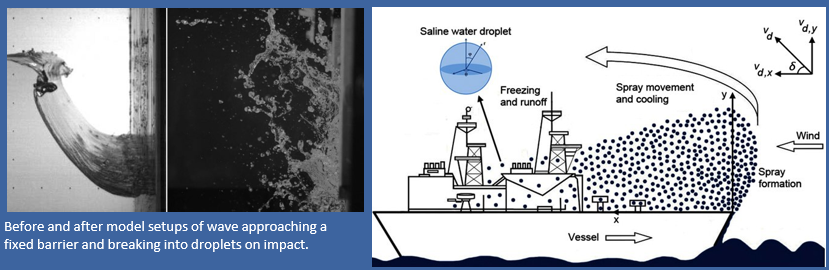

- Wave impact spray generation resulting in freezing spray; with and without wind assist.

- Modelling impact forces.

- Ocean, Naval, Aeronautical, Civil, Mechanical applications and other “harsh” conditions.

|

Wind Tunnel Air Temperature and velocity: |

-20 C < T < 20 C; 0 < U < 30 m/s |

|

Wind Tunnel Spray System: |

Simulate atmospheric precipitation |

|

Wind Tunnel Floor panels: |

Removable |

|

Wave Basin: |

Ambient temperature, fresh water, seawater salinity |

|

Wave Height: |

0.5 m |

|

Simulations: |

Wave impact spray generation resulting in freezing spray; ice accretion simulation; modelling impact forces. |

Objectives

Determine how:

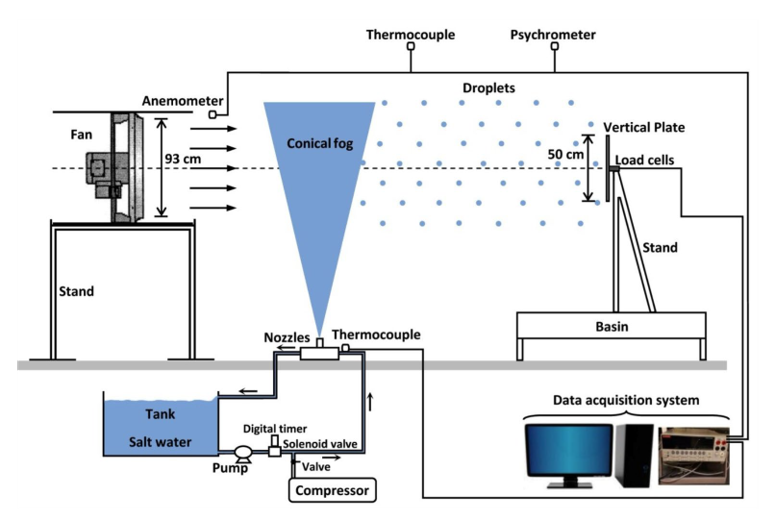

- Droplet size affects the amount of ice accretion

- Temperature of sea, air and vessel surfaces effect the icing process

- Sea spray ice accretion occur on different surfaces

- Gravity and salinity effect marine icing phenomena

Determine how to:

- Monitor parameters for accurate prediction of icing

- Monitor the amount of icing on a given structure

- Scale results of model scale icing experiments to full scale

- Develop de-icing strategies

Current experimental process in FEAS Cold Room

Typical experimental results

Cold room

- Cold Room: 18.5m L x 7.5m W x 9.5m H. 10-ton overhead crane.

- Design temperature : +5 C to ‐25 C

- Location of the SLIDE apparatus

- Specimens: Test structures or ice sheets; max. ice sheet 6 m L x 3m W x 2m H (grown in tank); fresh water, seawater salinity.