Safety and Risk Engineering Laboratory

About | People | Equipment | Location

About

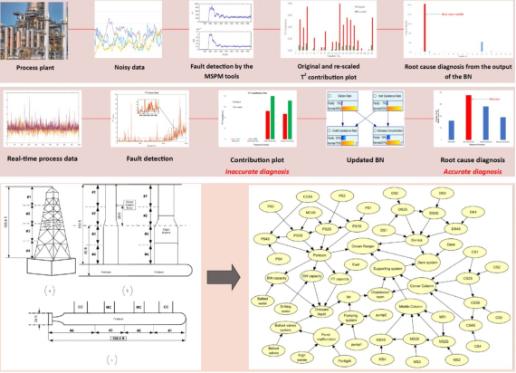

The Safety and Risk Engineering Research Lab facilitates research that will lead to the development of new technologies for safer and greener design, operation and maintenance of industrial processing facilities operating in challenging conditions and remote locations.

The lab-scale pilot plant (with funding of over $450,000 provided by Vale Inc. and the Atlantic Canada Opportunities Agency) was established to test and evaluate dynamic risk assessment models and to verify which models provide a reliable indication of process safety performance. The main goal is to apply the knowledge gained to real-life industrial applications, such as detection systems; to educate and train highly qualified personnel who will help advance the mission of sustainable, safe and green development of natural resources; and to improve risk management decision-making.

Research activities and resources available at Safety and Risk Engineering Research Labs include:

C-RISE (Centre for Risk, Integrity and Safety Engineering)

Graduates Office (ER 4015)

- Three High-Performance Computer (HPC) stations

- Account management for conducting high intensive simulations

- Full research licenses for ANSYS CFD, FSI, etc.

Simulation Lab (IIC 1024)

- 15+ computers available to graduate students

- Software installed for research

- Fault Tree and Event Tree Analysis FaultTree+ (Isograph), PTC Windchill FTA

- Bow-Tie Development BowTiePro, THESIS Bowtie

- Reliability Block Diagrams PTC Windchill RBD

- Bayesian Networks HuginExpert, Netica, Genie, Bayes Server

- Petri Nets and Markov Chains GRIF

- Process Modeling Aspen HYSYS

- Failure Modes, Effects and Criticality Analysis PTC Windchill FMEA

- Process Hazards Analysis (HAZOP, HAZID, What-if) IHS PHA-Pro HAZOP+ by Isograph, HAZOP Manager, PHAWorks, SheelHAZOP

- by SHEEL Technologies

For more details about research activities at Safety and Risk Engineering Research Labs, click here.

People

- Dr. Salim Ahmed

- Safety and Risk Engineering

- Process Systems

- Process Control

- Modelling and Simulation

- System Identification

- Dr. Syed Imtiaz

- Process Monitoring

- Process Control

- Modelling and Simulation

- Dr. Yan Zhang

- Energy

- Green Engineering

- Process System

- Simulation

- Dr. Susan Caines

- Asset Integrity Management

- Marine Corrosion

- Corrosion under Insulation (CUI)

- Dr. Faisal Khan

- Green Engineering

- Mineral Processing

- Offshore and marine safety

- Safety and Risk

Equipment

The Safety and Risk Engineering Research Laboratory is comprised of four labs and the equipment in each lab is listed accordingly.

Corrosion Lab

Located in IIC 1018

|

|

Located in Argentia, Newfoundland

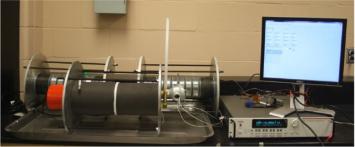

Managed Pressure Drilling Lab

Located in IIC 1024

- Determines early detection of uncontrolled influx or kick and loss of circulation and controls them

- Development of the robust advanced control algorithm to control the BHP by manipulating choke valve and backpressure pump

- Studies loss of circulation and kick situation

- Data collection for model validation

- Testing and validation of dynamic operational risk management system

Safety Engineering Lab

Located in IIC 1013

|

|

- Development of a new approach to model extreme weather load and leads to the development of risk-based winterization method

- Development of new knowledge and test procedures to preserve assets from harsh environmental operating conditions

- Development of testing protocols to investigate the effects of single and combined environmental factors on spray icing and propose testing procedures for equipment required by POLAR code.

- Practical learning in the control of three commonplace variables in process engineering: level, flow rate and temperature

- Simulation of typical industrial process faults; e.g., sensor failures, cable breaks, etc.

- Two industrial controllers are employed as the master and slave controller in the implementation of cascade control

- PLC to monitor safety devices and Profibus DP interface

- Demonstrate the effectiveness of innovative control technology in a pilot-scale plant

- Provide a bridge between theoretical knowledge and industrial practice in industrial instrumentation set up

- Development of fault diagnosis and alarm generation protocol for a set up more than one monitoring variable; e.g., temperature, water level, etc.

Computer Simulation Lab

Located in ER 4015

Location

Bruneau Centre for Research and Innvoation

Memorial University of Newfoundland

St. John's, NL