Soil-Pipe Interaction Research Laboratory (SPIRL)

About

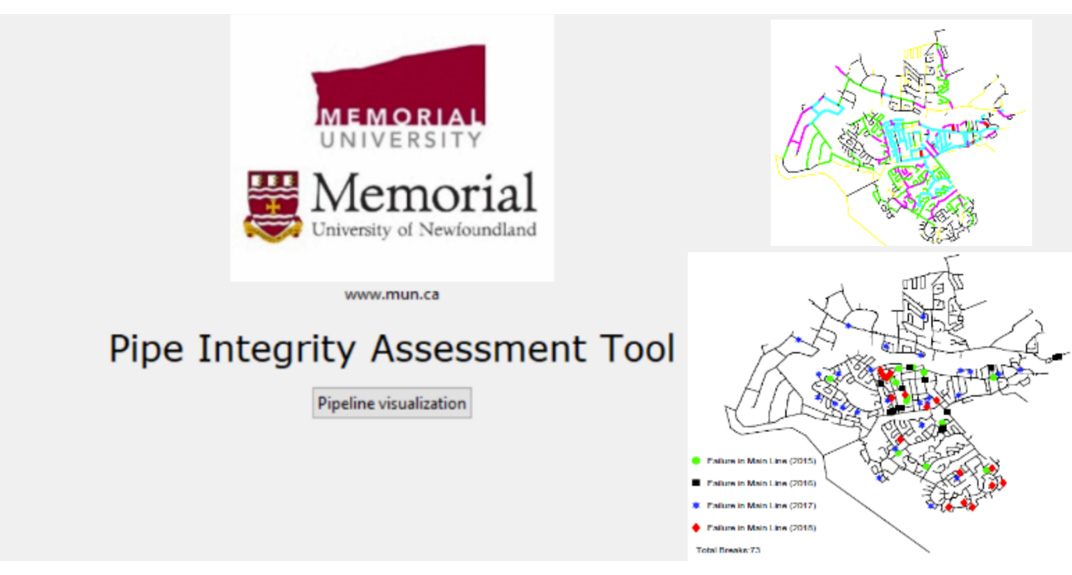

Under the direction of Dr. Ashutosh Sutra Dhar, the soil-pipe interaction research lab in the Department of Civil Engineering at Memorial University develops tools for risk-informed decision-making for the integrity of urban water and energy transmission and distribution pipe systems.

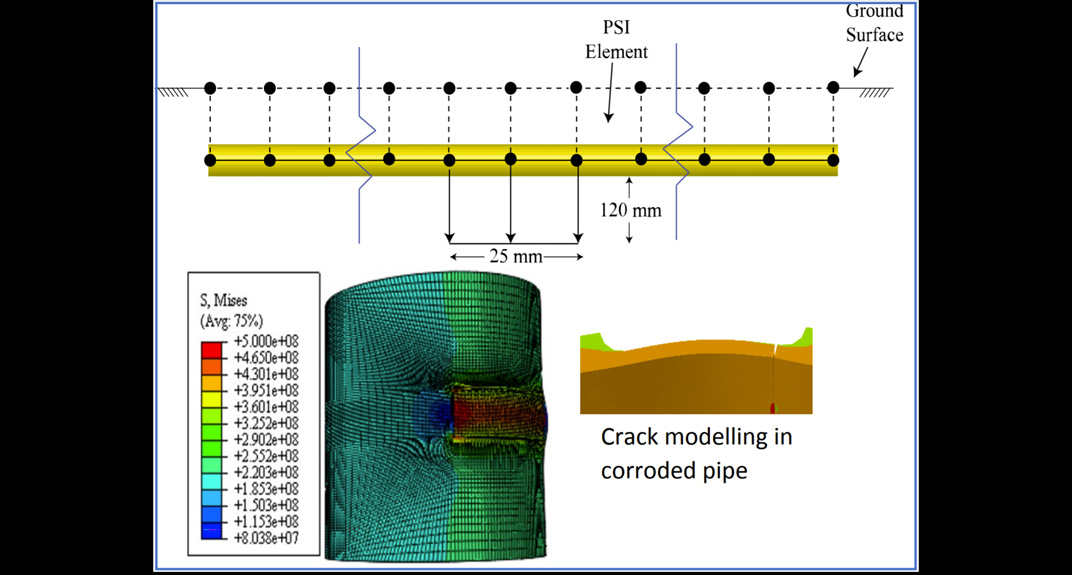

The major focus of this research includes the assessments of pipelines subjected to ground movements, the remaining strength assessment of corroded pipelines, leak detection using the acoustic emission method, and the development of municipal pipe integrity assessment tools.

Collaborators

- Dr. Ashutosh Sutra Dhar

- Mechanics of soil-pipe interaction

- Limit states of municipal and energy pipelines

- Pipelines subjected to ground movements

- Remaining strength of deteriorating pipelines

- Pipeline integrity management

- Finite element modelling and full-scale testing

- Dr. Bipul Hawlader

- Geotechnical engineering

- Large-scale landslides and run-out

- Onshore and offshore oil and gas pipelines

- Pile foundations

- Riser-seabed-water interaction

- Large deformation behaviour of soil

- Numerical analysis

- Centrifuge modelling

- Laboratory testing

- Dr. Hodjat Shiri

- Climate change induced coastal erosion and flooding

- Sustainable coastal and offshore infrastructures and resilience

- Fluid-soil-pipeline interaction

- Fatigue performance of deepwater risers

- Arctic seabed hazards and its impact on subsea flowlines and subsea structures

- VIV fatigue performance and the integrity of subsea flowlines

- Offshore foundations and geotechnique

- Arctic subsea renewable energies

- The impact of seabed hazards on mobile jackup units

- Catenary mooring and performance of anchoring systems

- Subsea and offshore installation techniques

- Offshore construction challenges

- Dr. Sam Nakhla

- Material degradation and failure analyses for the prediction of remaining life with focus on their applications in aerospace, mechanical and biomedical engineering

Equipment

The following facilities are available for laboratory testing and numerical modelling:

- Full-scale pipe test facility to simulate the effects of axial, lateral, and oblique ground movements on pipes and joints. The facility is equipped with:

- A 4m x 2m x 1.5m steel tank capable of holding 12 m3 of soil. A conveyor belt is available for moving soil from and to the tank.

- Null gauges, tactile pressure sensors, and RST vibrating wire pressure cells for earth pressure measurements.

- Strain gauges and LVDT for pipe response measurements.

- LUNA ODiSI 6108 Distributed Sensing Instrument with an 8-channel controller to measure pipe strains as well as soil deformations (purchasing in progress).

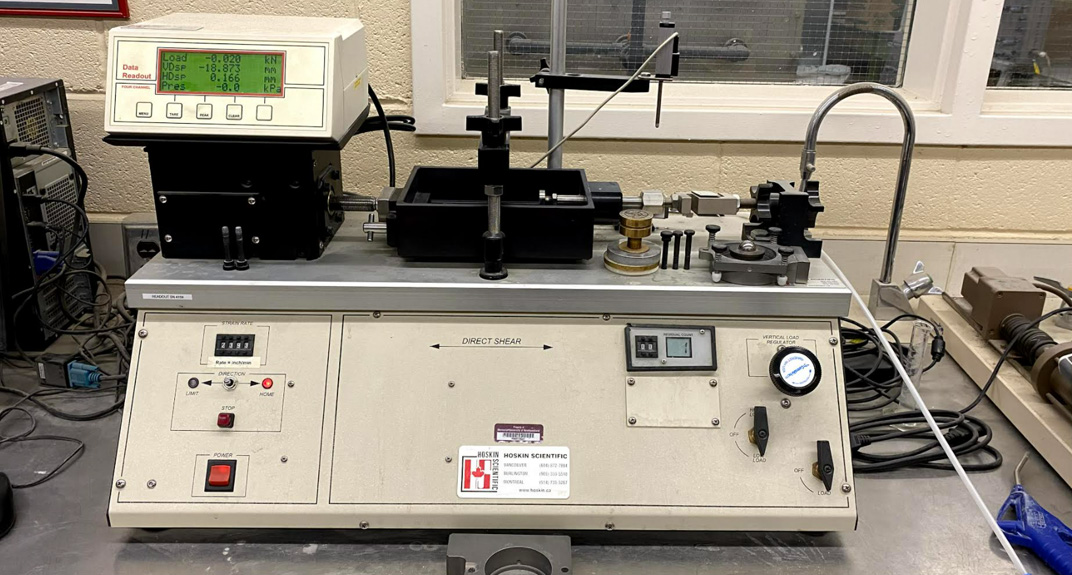

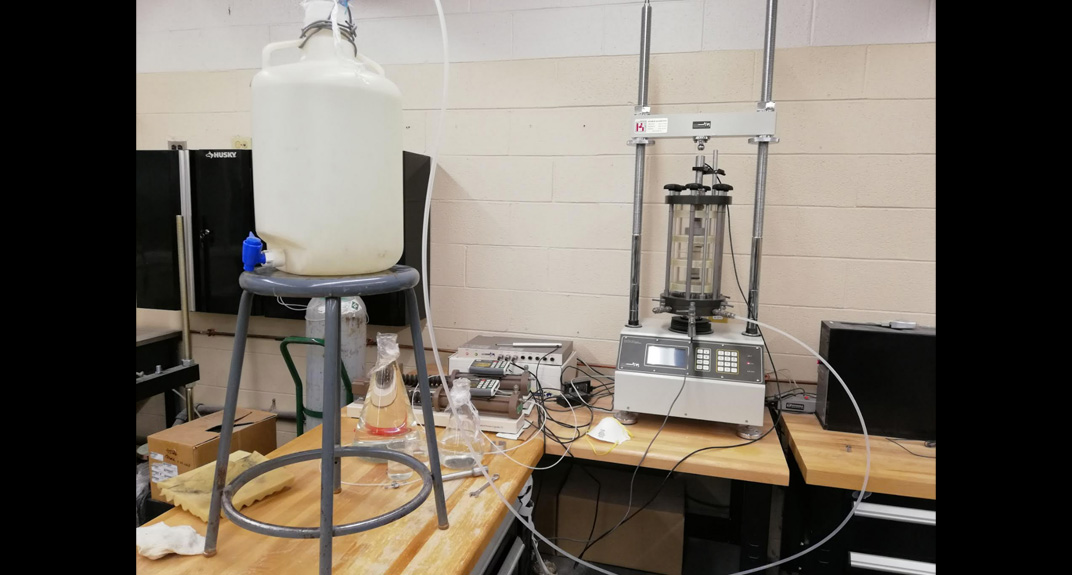

- Standard Geotechnical testing facility including triaxial, direct shear, unconfined compression, consolidation, and field density measuring (sand cone method) apparatus.

- Acoustic sensors for measuring acoustic wave propagation through the pipe wall

- Licensed Abaqus FE software for numerical modelling. Also, we use programming in Python for developing interface and analysis tools.

Location

EN 1026, EN 1033

Faculty of Engineering and Applied Science

Memorial University of Newfoundland

St. John's, NL