Reservoir Management and Production Optimization

About | Team | Publications | Contact |

About

Reservoir management encompasses the strategic oversight of oil and gas reservoirs throughout their lifespan. It involves various activities, including reservoir characterization, monitoring, and modeling, with the goal of maximizing production and recovery. The primary objective is to efficiently utilize resources, minimize costs, and maximize profitability. However, relying solely on experience or passively reacting to reservoir feedback may not lead to an optimal reservoir production strategy from a reservoir engineering perspective.

Reservoir simulators serve as essential tools for investigating different scenarios related to reservoir management and production optimization. However, even with simulators, achieving accurate results in a timely manner has always been a challenge. Reliable decision-making often requires numerous simulations runs to be performed, which can be computationally intensive. This is where artificial intelligence (AI) comes into play, as it has the potential to alleviate the computational burden associated with simulators.

Our team has successfully executed several projects focused on reservoir management and production optimization. In the following sections, we will provide a brief overview of these projects and their outcomes.

1. Screening and Production Optimization Using Smart Proxy Modeling

It is essential to regularly update the screening of fluids movement within the reservoir, production optimization, and any field development plans in shorter timeframes. Conducting real-time analysis can greatly benefit in comprehending the evolving conditions in the reservoir. However, the use of real-time analysis is often constrained due to the expensive computational cost of using simulators. Therefore, this project has explored the implementation of computationally efficient proxy models (PM) as an alternative solution.

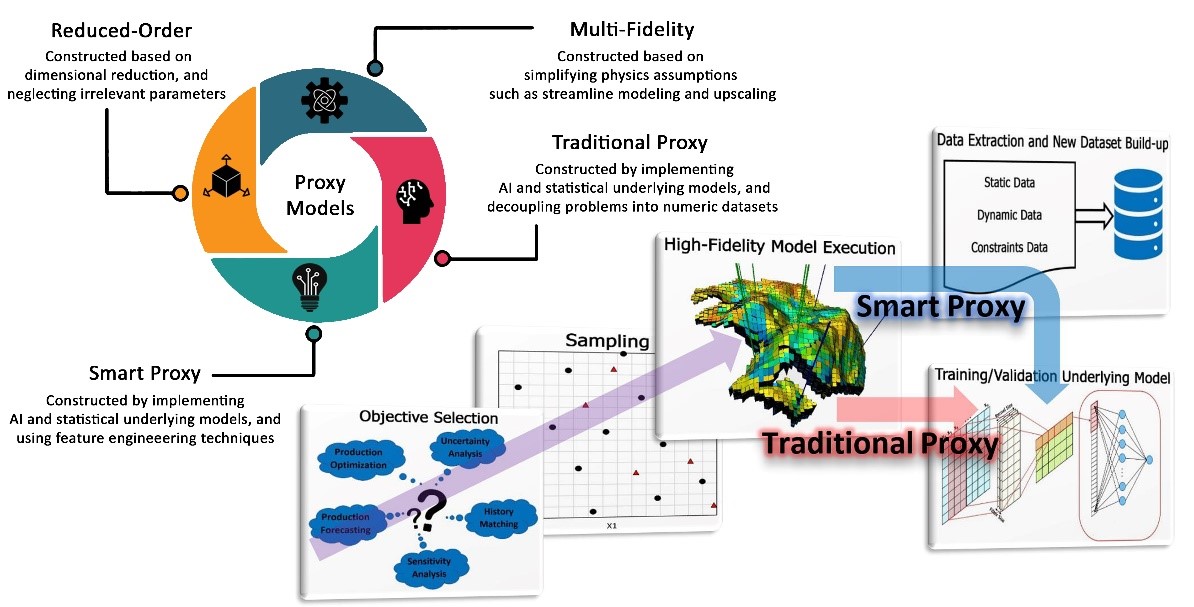

Figure 1: Proxy modelling classification and the workflow to develop traditional and smart proxy models.

PMs can be classified into various classes as shown in Figure 1. Two classes of traditional and smart proxy models usually implement statistical/AI-driven models. The methodology of constructing traditional proxy models (TPM) includes running the numerical models, recording the outputs, and making a relationship between the inputs and outputs. TPMs usually require a higher number of numerical models runs and suffer in terms of prediction accuracy. As with traditional models, smart proxy models (SPM) also create a methodology to relate inputs to outputs. However, SPMs work based on pattern recognition and machine learning methods and have additional steps in the construction process compared to TPMs. The main additional steps in SPM construction are extracting new static/dynamic parameters and forming a new dataset. The newly extracted parameters help to capture unseen patterns within the reservoir under investigation.

In this project, we conducted two case studies on the VOLVE and NORNE offshore reservoirs, specifically focusing on waterflooding and water-alternating-gas (WAG) scenarios. In both cases, we accurately forecasted fluid movement and production by employing a convolutional neural network as the underlying model for the SPM. The SPM exhibited an accuracy of over 94% compared to the simulator. To optimize the process, we integrated the constructed SPM with derivative-free algorithms such as genetic algorithm (GA) and particle swarm optimization (PSO). The final results demonstrated that the SPM significantly reduced the computation time for a single run from 5 hours to a mere 5 seconds.

2. Water-Alternating-Gas Optimization Using Derivative-Free Algorithms

WAG is an enhanced oil recovery method that integrates the improved displacement efficiency of the gas injection with an improved macroscopic sweep by water flooding to enjoy the advantages of both processes. This technique entails alternating injection of gas and water into the reservoir. Optimizing a WAG project entails the optimization of design parameters such as the water and gas rates, cycle length, cycle ratio, etc. which are described in more detail in the following.

The optimal design of the WAG parameters can be based on numerical reservoir simulation via trial and error or by employing optimization techniques to guide the simulation runs and reduce the number of function evaluations. We have utilized robust evolutionary algorithms to optimize hydrocarbon WAG performance in the E-segment of the Norne field.

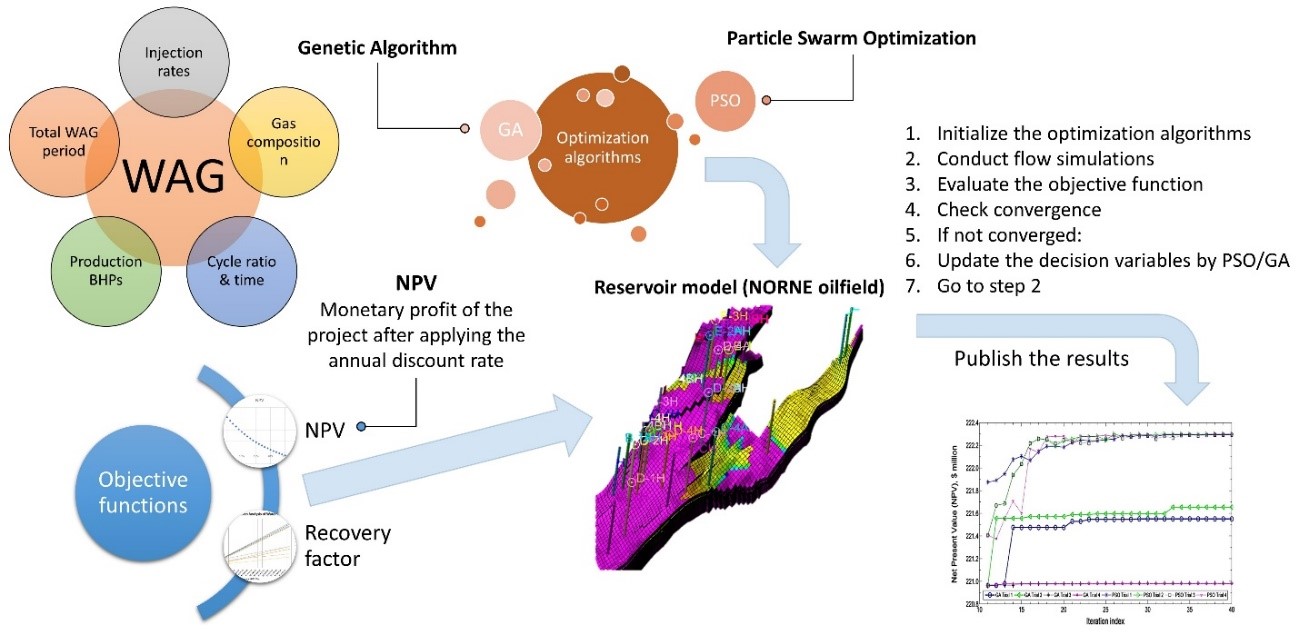

The first objective function was selected to be the net present value (NPV) and two global semi-random search strategies, a genetic algorithm (GA) and particle swarm optimization (PSO) were tested on different case studies with different numbers of controlling variables, which were sampled from the set of water and gas injection rates, bottom-hole pressures of the oil production wells, cycle ratio, cycle time, the composition of the injected hydrocarbon gas (miscible/immiscible WAG) and the total WAG period. The second objective function was the incremental recovery factor (IRF) within a fixed total WAG simulation time and it was optimized using the same optimization algorithms. A reference case was first obtained for the experiments by means of design of experiments (DOE) and then both GA and PSO were tried four times on each of the NPV optimization experiments and three times on the experiment of oil recovery optimization with the same initial guesses for each experiment. Figure 2 shows the overall workflow of the presented approach.

Figure 2. Overall Workflow of the WAG Optimization of the WAG optimization approach

Figure 2. Overall Workflow of the WAG Optimization of the WAG optimization approach

For the optimization with the NPV as the objective function, the improvement was from 8.2% to 14.2% compared to the reference cases where PSO could achieve slightly better results than the GA. In the experiment of oil recovery optimization, PSO and GA showed an improvement of about 16.2% and 14.2%, respectively, compared to the reference case.

3. Well Placement Optimization Using Derivative-Free Algorithms

Maximizing production from an oil field is a critical task that involves making strategic decisions regarding well placement and control of injection and production rates. These decisions have a significant impact on production outcomes, such as preventing premature water breakthrough and maintaining reservoir pressure while achieving high flow rates. Due to the multitude of potential development scenarios, efficient computerized optimization approaches are necessary to assist in making decisions. Typically, well placement and well control problems are treated separately, with optimization focused on parameters related to the positions and orientations of injection and production wells.

To address this challenge, we explored the use of two optimization algorithms: particle swarm optimization (PSO) and generalized pattern search (GPS) on the NORNE reservoir model. These approaches aimed to optimize both well placement and control parameters simultaneously. By combining these algorithms, we can jointly optimize the placement of new wells and adjust control parameters for existing wells. This integrated approach provides advantages over treating well placement and well control problems independently.

A unified approach to optimizing well placement and control offered several benefits. It recognized that the optimal well configuration when producers are fixed at a specific bottomhole pressure (BHP) may differ from the best configuration when control parameters can vary over time. Our investigation employed PSO and GPS algorithms to tackle this challenge. The hybridization of these algorithms allowed for simultaneous optimization of both placement and control parameters or sequential optimization in a decoupled approach, resulting in a comprehensive solution to the joint optimization problem.

Team

Dr. Lesley James

Prof. Lesley James is a Professor and former Chevron Chair in Petroleum Engineering in the Dept of Process Engineering at Memorial University. Dr. James’ research interests focus on sustainable oil production by increasing oil recovery rates through enhanced and improved oil recovery (EOR & IOR). Currently, her focus is on maximizing recovery from offshore Newfoundland and Labrador oil and gas fields through understanding the fluid-fluid and rock-fluid interactions and particularly examining miscible/near-miscible fluid injection and optimal EOR strategies for offshore production. Working closely with industry, Dr. James is currently working on the use of CO2 for offshore oil recovery from complex reservoirs, integrated operations for maximising oil recovery in remote harsh locations, water-alternating-gas (WAG) using produced natural gas for Hibernia, EOR screening and production optimisation for Hebron, and using Digital Oilfield technologies to increase production and reduce costs.

Dr. James has been awarded the Society of Petroleum Engineer’s Distinguished Achievement Award for Petroleum Engineering Faculty and serves as mentor for the Student Society of Petroleum Engineers (SSPE), the Student Society of the European Association of Geoscientists and Engineers (EAGE), and the Student Metallurgy & Materials Society (MetSoc). Lesley is a Professional Engineer of Newfoundland and Labrador (PEGNL), is a member and past-president of the Society of Core Analysts (SCA), a member and Atlantic section board member of Society of Petroleum Engineers (SPE), a member of the Canadian Society of Chemical Engineers (CSChE), and the American Society of Chemical Engineers (AIChE), and the European Association of Geoscientists and Engineers (EAGE).

Phone: 709-864-2485

Email: ljames@mun.ca

Office: IIC1019

Dr. Ronald Haynes

Prof. Haynes was born and raised in Newfoundland and Labrador. He completed his BSc (Hons) at Memorial, and followed this with a Master's and PhD at Simon Fraser University and then post-doc at the University of Waterloo in 2004. After five years at Acadia University, he returned home to Memorial in 2009 where he is now a Professor in the Department of Mathematics and Statistics. His research foci include the adaptive and parallel numerical methods for the solution of partial differential equations and the solution of large scale, often industrially relevant, optimization problems. His research and scholarly activity are collaborative and multidisciplinary, and lives at the crossroads of applied mathematics, computational science and engineering, with practical applications to industry. Over the last ten years he has worked on optimal oil well placement and control problems and optimizing WAG scenarios. As principal investigator or co-investigator, he has secured approximately $3.5 million in research funds. Dr. Haynes has co-authored nearly 60 publications and supervised six postdoctoral fellows, 25 graduate students and 30 undergraduate research students. In 2018 he was granted the President’s Award for Outstanding Research at Memorial.

Phone: 709-864-8825

Email: rhaynes@mun.ca

Office: HH-3032

.jpg)

Dr. Erfan Mohagheghian

Erfan is a PhD graduate from the University of Calgary with a focus in reservoir engineering. He obtained his MSc in Oil and Gas Engineering from Memorial University and has a Bachelor’s degree in petroleum engineering from the Amirkabir University of Technology. He worked as a seasoned data analyst on the project where his vast experience in reservoir engineering was beneficial to the team.

(1).jpg)

Peyman Bahrami

Peyman worked as a full-time research assistant and a PhD candidate at Memorial University in Oil and Gas Engineering. His educational background is in Oil and Gas engineering, for both Master’s and Bachelor’s degrees. Peyman has industrial experience in the upstream section of oil and gas. His research interests are numerical simulation, enhanced oil recovery, and data analysis in big data problems.

Publications

- P. Bahrami, F. Sahari Moghaddam, and L. A. James, “A review of proxy modeling highlighting applications for reservoir engineering”, Energies, 15 (14), 2022, doi: 10.3390/en15145247.

- P. Bahrami and L. A. James, “Screening of waterflooding using smart proxy model coupled with deep convolutional neural network”, Geoenergy Science and Engineering, 221, p. 111300, 2023, doi: 10.1016/j.petrol.2022.111300.

- P. Bahrami and L. A. James, “Field Production Optimization Using Smart Proxy Modeling; Implementation of Sequential Sampling, Average Feature Ranking, and Convolutional Neural Network”, Presented at 23 SPE Canadian Energy Technology Conference and Exhibition, Calgary, Canada, March 2023, SPE-212809-MS, doi: https://doi.org/10.2118/212809-MS

- E. Mohagheghian, L. A. James, R. D. Haynes, “Optimization of hydrocarbon water alternating gas in the Norne field: Application of evolutionary algorithms”, Fuel, 223, 2018, doi: https://doi.org/10.1016/j.fuel.2018.01.138.

- E. Mohagheghian, “An application of evolutionary algorithms for WAG optimization in the Norne Field“, Master thesis, Memorial University of Newfoundland, 2016: https://research.library.mun.ca/12108/

- T. D. Humphries, R. D. Haynes, “Joint optimization of well placement and control for nonconventional well types“, Journal of Petroleum Science and Engineering 126, 242-253, 2015. doi: https://doi.org/10.1016/j.petrol.2014.12.016

- T. D. Humphries, R. D. Haynes, L. A. James, “Simultaneous and sequential approaches to joint optimization of well placement and control“, Computational Geosciences 18, 433-448, 2013, doi: https://doi.org/10.1007/s10596-013-9375-x

- T. D. Humphries, R. D. Haynes, L. A. James, “Simultaneous optimization of well placement and control using a hybrid global-local strategy“, ECMOR XIII-13th European Conference on the Mathematics of Oil Recovery, 2012, doi: https://doi.org/10.3997/2214-4609.20143204.

Contact

|

Faculty Member |

Contact Info |

|

Lesley James |

Phone: 709-864-2485 Email: ljames@mun.ca Office: IIC1019 |

|

Ronald Haynes |

Phone: (709) 864-8825 Email: rhaynes@mun.ca Office: HH-3032 |

Faculty of Engineering and Applied Science

Memorial University of Newfoundland

St. John's, NL