Design/Materials

About

The research area of mechanics and materials is involved in the study of welding and joining advancement of engineering materials, corrosion science and engineering, the study of ice characterization field studies, the model and simulation of vibrations in drilling and advanced materials and manufacturing processes.

Facilities

-

Composites Lab

-

Ice Mechanics Lab

-

Materials Characterization Lab

-

Rapid Prototyping Facility

-

Vibrations Lab

-

Welding Lab

People

-

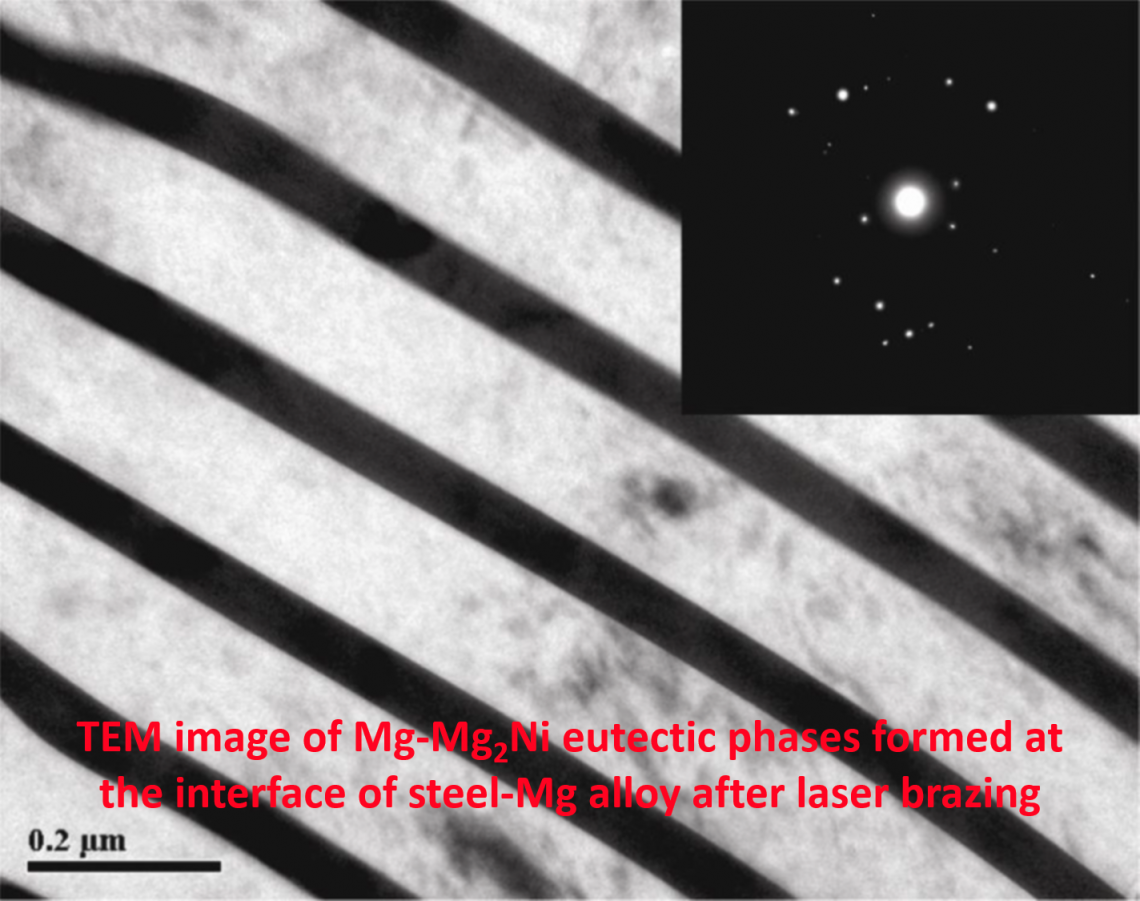

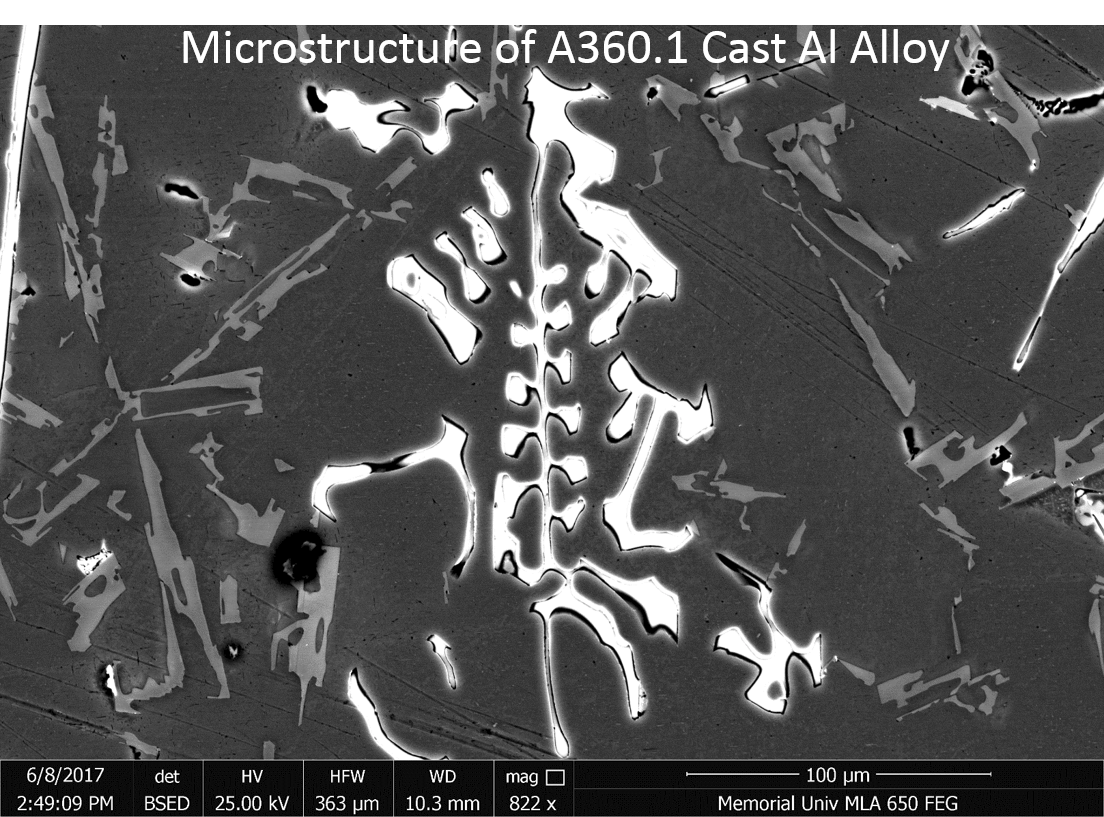

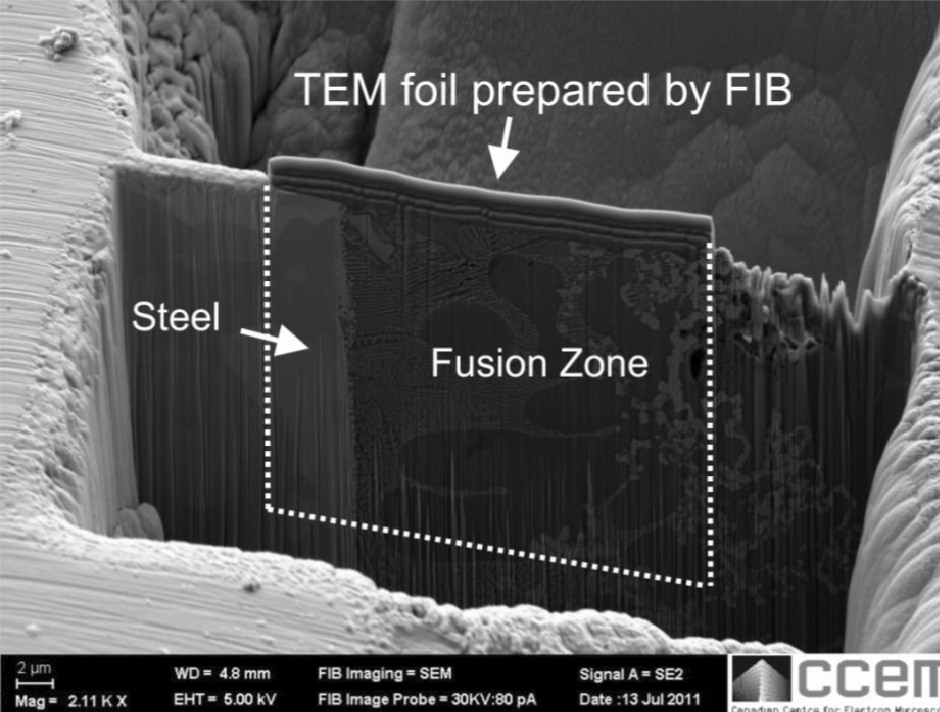

Dr. Ali Nasiri (Adjunct Professor)

-

Dr. Anand Sharan

- Energy, Environment, Machine Tools, Robots, and Rotor Dynamics including Turbines for Aircraft, and Power Generation Industry.

-

Dr. Andy Fisher (Retired Professor)

-

Dr. James Yang

- Random Vibration/Dynamics of Mechanical Systems and Fatigue Prediction under Random Loading

-

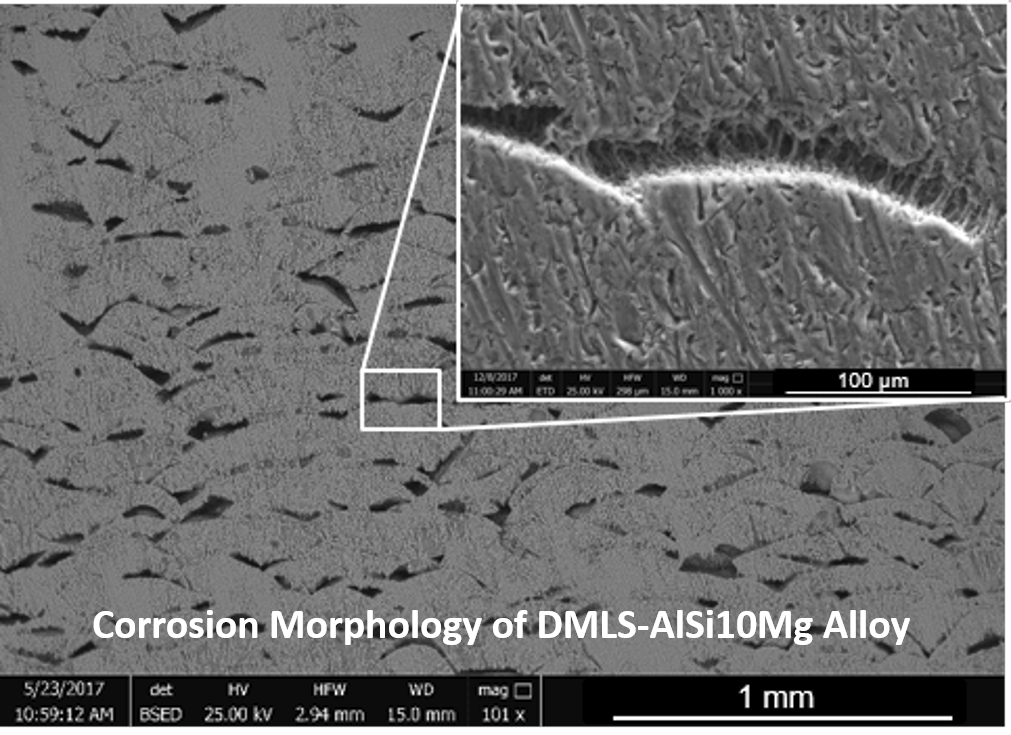

Dr. Sam Nakhla

- Computer-aided design (CAD) and finite element analysis (FEA) for Modeling, Simulation, Analysis and Design, Structural Health Monitoring (Metal Corrosion and Composites), Modeling and Simulation of Medical Equipment

-

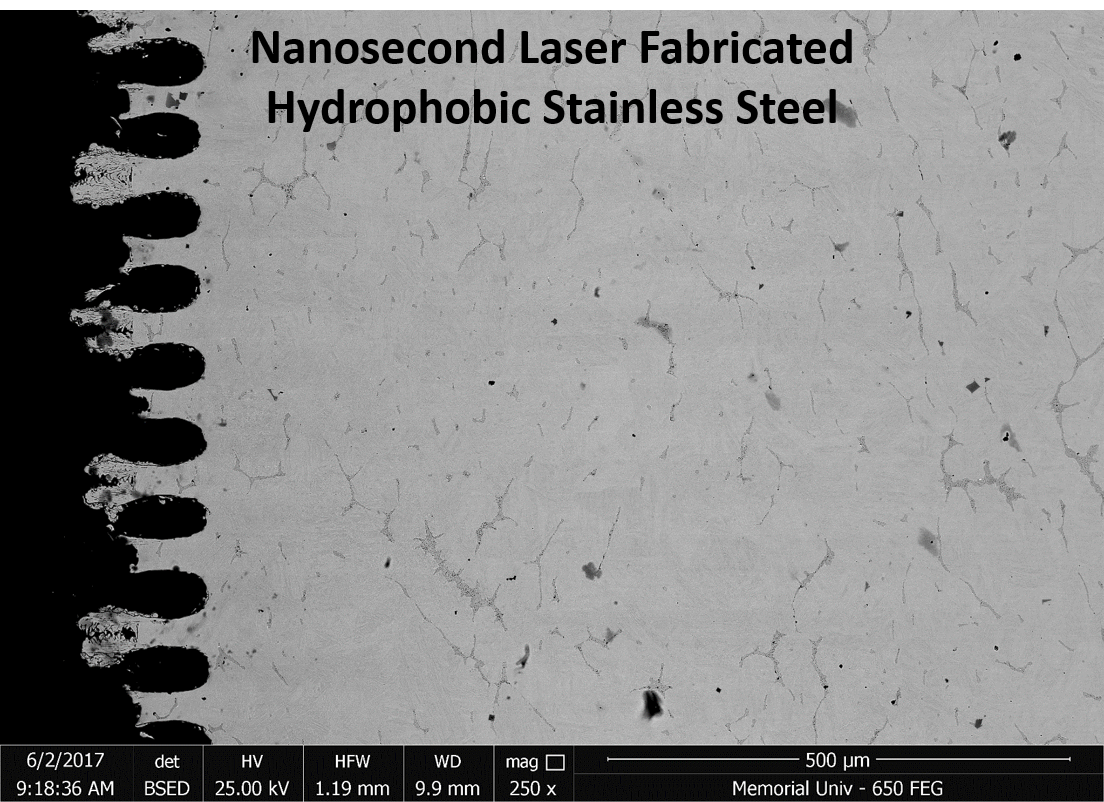

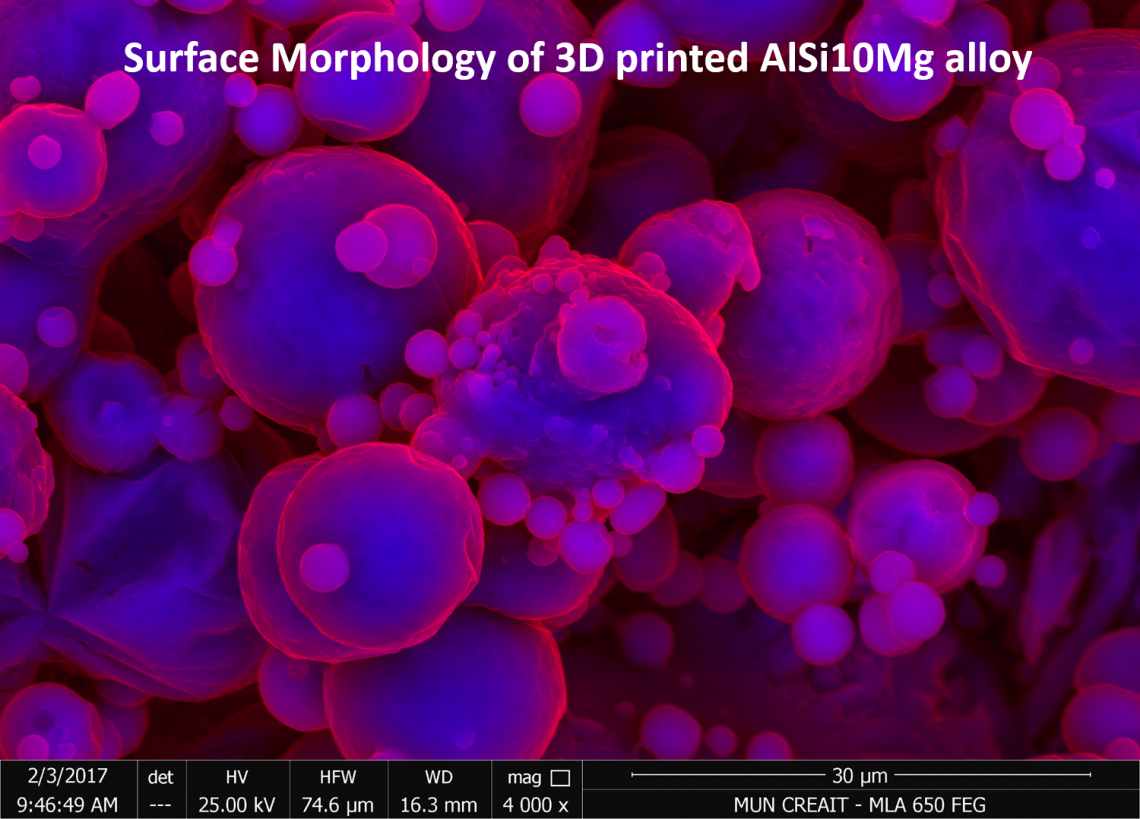

Dr. Sima Alidokht

- Surface Engineering, Coatings Tribology, Corrosion and Tribo-Corrosion Science and Engineering, Thin Films, Metal Additive Manufacturing, Microstructure, and Multi-Scale Mechanical Properties Testing.

Equipment

The Materials Characterization Research Facility has the following equipment.

Analytical Equipment

- Mechanical Testing Load Frame

- Dynamic Non-contacting Video Extensometer

- Hardness Tester & Vickers Micro-Hardness Tester

- Optical Microscope

- Scanning Electron Microscope

Specimen Preparation Equipment

Welding Equipment

- Robotic Gas Metal Arc Welding Cell

- Millermatic 212 Auto-set GMAW Power Source (Qty: 2)

- Millermatic 252 GMAW Power Source

- Dynasty 200 SD GTAW/SMAW Power Source

Corrosion Testing Equipment

- Proof Ring Systems

- Portable Electrochemical Interface & Impedance Analyzer

- HP/HT Dynamic Autoclave

- Environmental Chamber

- Salt Spray Chamber

Vibration Equipment

- Model Test System

- Reduced-Scale Electrical Pole Line

- Full-scale Pole Destructive Test System

- Quarter-car Suspension Test Rig

Analytical Equipment

. . .Mechanical Testing Load Frame: Instron E10000 Linear-Torsion All-Electric Dynamic Test Instrument

This equipment is designed to test full range of dynamic and static-loading situations on various materials and components.

- High dynamic performance (up to 100 Hz)

- ±10 kN dynamic linear load capacity and ±100 Nm dynamic torque capacity. Dynamic torque capacity is approximately 100 Nm.

- Includes a 3119-605 Environmental Chamber (Temperature range: Ambient to +350oC).

Back to list of analytical equipment

.

.

.

.

.

.

.

.

.

. . .Dynamic Non-contacting Video Extensometer (Instron AVE 2)

This equipment can perform non-contacting strain measurements under static or even cyclic loading condition.

Specifications

- Capable of tracking displacement of up to 500mm/s with cyclic test frequencies of up to 20Hz.

Back to list of analytical equipment

.

. . .Hardness Tester & Vickers Micro-Hardness Tester

This equipment tests the hardness of a wide range of metallic or non-metallic materials.

- Wilson Rockwell 574 Superficial Tester

- Hardness Scales: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y

- Test Loads: 15, 30, 45 Kg

Back to list of analytical equipment

.

.

.

.

.

.

. . .Optical Microscope

This Nikon Eclipse 50i is an upright optical microscope.

Specifications

- 5x, 10x, 20x, 50x, and 100x Infinity Objectives

- Included an Image Pro analysis software.

Back to list of analytical equipment

.

.

.

.

. . .Scanning Electron Microscope

This JCM-6000PLUS NeoScope Benchtop provides SEM imaging and compositional analysis capabilities in our lab.

- Resolution: up to 60,000X

- Multi-touch screen interface for intuitive operation

- Secondary electron and solid state backscattered electron detector

- Motor drive stage and EDS

Back to list of analytical equipment

.

Specimen Preparation equipment

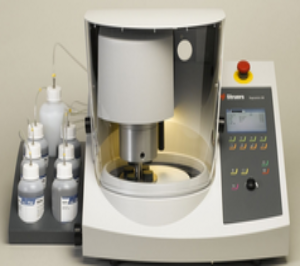

. . .Hot Mounting Press: CitoPress-30

This equipment is an advanced, electro-hydraulic hot mounting press with two cylinders.

- Pressure: 50-350 bar / 725-5076 psi

- Heating time: 1-15 min

- Heating temperature: 80-180oC

- Cooling time: 1-15 min

Back to list of specimen preparation equipment

.

.

.

. . .Auto-grinder/polisher: Tegramin-3 Struers

This equipment is an automatic, microprocessor controlled machine for grinding and polishing of specimens on 300 mm MD-Disc with cone.

Back to list of specimen preparation equipment

.

.

.

. . .Sand Blaster: ProBlast

This precision-controlled abrasive blasting system can be used for sandblasting of various metallic and non-metallic surfaces in an enclosed chamber.

Specifications

- Pressure delivery system: 0-100 psi

- Blasting media: all tuypes from 60 to 360 grit (25-250 micron)

Back to list of specimen preparation equipment

.

.

.

Welding equipment

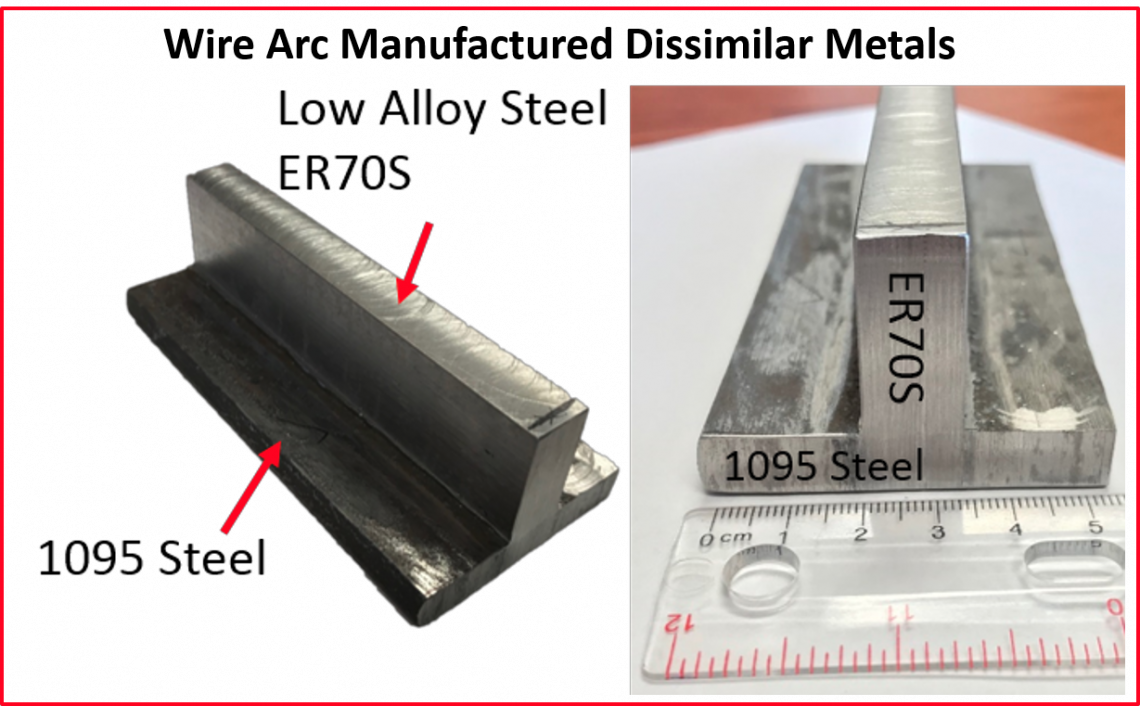

. . .Robotic Gas Metal Arc Welding Cell

This robotic cell is used for fusion welding of similar and dissimilar metal combinations, and also wire arc manufacturing for various industrial applications.

Specifications:

- FANUC ARC Mate® 50iD/7L Six Axis Mechanical Unit

- Power Wave® R350 and AutoDrive® 4R100

- Processes: GMAW-STT®, SMAW, GMAW, GMAW-P, GTAW

Back to list of welding equipment

.

.

.

.

. . .Millermatic 212 Auto-set GMAW Power Source (Qty: 2)

This is a MIG welding machine capable of welding materials from 22 guage to 3/8 in. thick, in a single pass.

Specifications

- Processes: MIG (GMAW), Flux Cored (FCAW)

- Welding Amperage range: 30-210 Amps

- Wire Speed: 50-700 IPM (1.3-17.8m/min)

Back to list of welding equipment

.

.

.

.

. . .Millermatic 252 GMAW Power Source

Having the highest output in its class, this MIG welding machine is capable of welding materials from 22 guage to 1/2 in. thick in a single pass.

Specifications

- Processes: MIG (GMAW), Flux Cored (FCAW)

- Welding Amperage Range: 30-300 Amps

- Wire Speed: 50-700 IPM (1.3-17.8m/min)

Back to list of welding equipment

.

.

.

.

. . .Dynasty 200 SD GTAW/SMAW Power Source

This adanced welding unit offers combined AC/DC TIG with SMAW capabilities.

Specifications

- Processes: GTAW (AC/DC), SMAW (AC/DC)

- Input power: 115-460 V

Back to list of welding equipment

.

.

.

.

Corrosion Testing Equipment

. . .Proof Ring Systems (Qty: 10)

Proof ring systems are an accurate way for determination of Hydrogen Induced Cracking (HIC) and Sulfide Stress Cracking (SSC) susceptibility of materials in harsh environments, e.g. H2S service.

Specifications

- Stress range: 150,000 ± 2% psi (~1034 MPa)

- Stress Corrosion Cracking testing capabilities as per NACE TM0177

Back to list of corrosion testing equipment

.

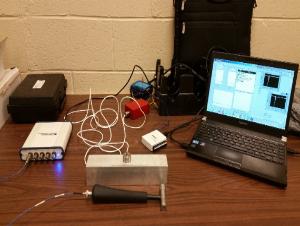

. . .Portable Electrochemical Interface & Impedance Analyzer

This unit provides capabilities of measuring the electrochemical properties of materials at various environmental conditions.

Specifications

- Product Analog in/out: 8/2 (0 to +4V, 16bit resolution)

- Product Digital input/output: 2/3 (0 to +5V)

- Product AC-out: ±0.5V sinewave 10µHz-3MHz with variable attenuation

- Product Channel-X input, Channel-Y input: +4V: to record impedance from peripheral devices

Back to list of corrosion testing equipment

.

. . .HP/HT Dynamic Autoclave (Qty: 2)

This equipment enables users to stimulate a broad range of temperature, pressure, and environmental conditions using mechanical and electrochemical corrosion testing techniques.

- 1 Gallon capacity.

- Operating Temperatures: up to 300oC (572oF).

- Operating Pressure: up to 35 MPa (5,076 psi).

Back to list of corrosion testing equipment

.

. . .Environmental Chamber

This chamber provides a controlled temperature environment and can accommodate all temperature testing requirements.

- Temperature range: -68 to 180oC

Back to list of corrosion testing equipment

.

. . .Salt Spray Chamber

This equipment is designed to perform salt spray accelerated corrosion testing and covers all testing requirements from continuous salt spray test to condensation humidity test.

Specifications

- Temperature range: ambient to +50oC

- Salt Spray fall-out rate: 0.5 to 2.5 mL per 80cm2 per hour

- Wetting mode: ambient to +50oC

- Drying mode: ambient to +50oC

Back to list of corrosion testing equipment

.

Vibrations Equipment

. . .Model Test System

The model test system is used to determine the frequency spectra, natural frequencies, and the damping ratios of numerous materials.

- Contains instrumented impact hammers of various sizes, accelerometers, amplification, and signal conditioning hardware.

Back to list of vibration equipment

.

. . .Reduced-Scale Electrical Pole Line

This equipment is used to measure the tension of the dynamic cable. Also used for repeatable experiments on the effect of conductors and the foundation on the vibration properties of poles.

- The poles are represented by steel bars of variable size, in a foundation that can be either rigid or compliant.

- Pole vibrations can be restricted to in-plane or out-of-plane with respect to the line direction.

Back to list of vibration equipment

.

.

.

.

.

.

.

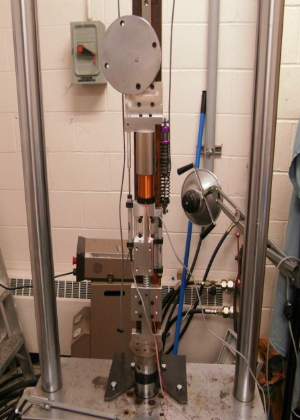

. . .Full-scale Pole Destructive Test System

This equipment applies load to the tip of a cantilevered pole, displacing it at a controlled rate to destruction while measuring the applied force and bending deflection and multiple locations.

- Consists of a winch with load cell, clamp for pole and displacement sensors

- Determines the yield and ultimate strength of the poles in accordance to the official standard (ASTM D1036-99).

Back to list of vibration equipment

.

. . .Quarter-Car Suspension Test Rig

This equipment consists of several components used to model a typical vehicle and measure variables such as the acceleration of a "sprung mass" and "unsprung mass," tire deflection, and suspension deflection.

- The "sprung mass" represents the vehicle body. The "unsprung mass" represents the wheels, tires and brakes.

- Other components includes the suspension spring/damper and tire spring. The hydraulic actuator is used to apply the vertical load motion.

- A linear motor can be inserted to create an active suspension system.