Interfacial Thermofluids and Energy Laboratory

About | People | Equipment | Location

About

We conduct fundamental research in thermodynamics, fluid mechanics and heat transfer, with applications in energy systems. We are particularly interested in phase change heat transfer (e.g., freezing and melting), multiphase flow (including nanofluids), and thermal hydraulic dynamics at the solid-liquid interface. The applications include thermal energy storage, thermal management, flow assurance and asset integrity and safety management in a harsh environment.

For details of our research activities and group members, click here.

People

- Dr. Xili Duan

- Heat transfer

- Phase change

- Energy storage

- Fluid mechanics

- Multiphase flow

- Thermal management

- Dr. Kevin Pope

- Chemically reactive multiphase flows

- Energy systems

- Energy storage

- Second Law applications to thermal / fluids

- Energy efficiency

- Process integration

- Dr. Yuri Muzychka

- Heat Transfer

- Fluid Dynamics

- Multiphase Flow

- Thermal Systems

- Thermal Management in Micro-electronic Packaging

- Dr. Baafour Nyantekyi-Kwakye

- Turbulent structures in separated and reattached flows

- Atomization in gas turbines

- River ice processes

- Ice jam and border ice stability

Equipment

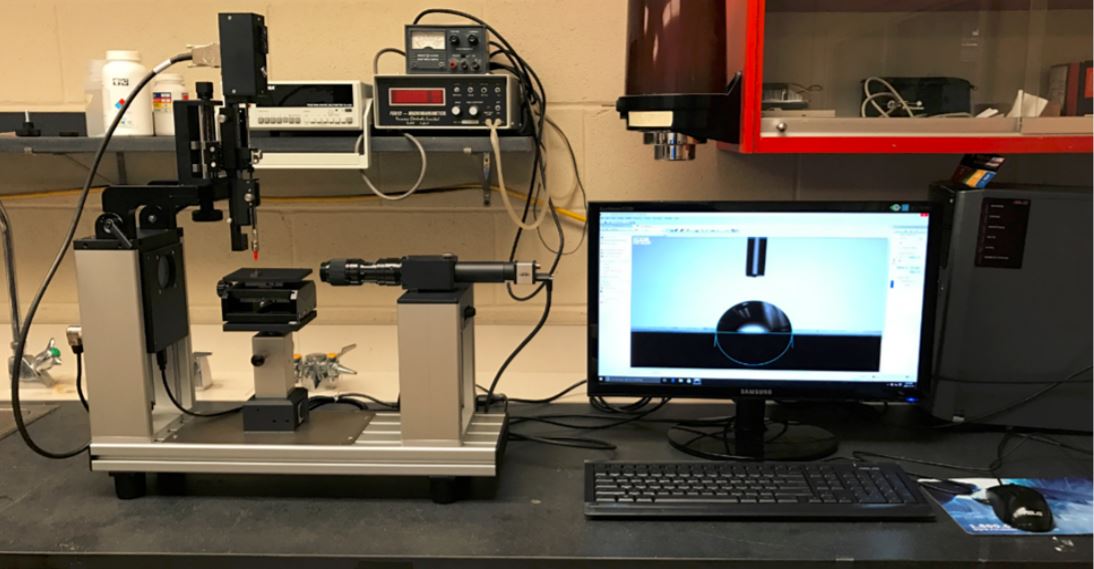

The Contact Angle Measurement System is used to characterize surface wettability. It measures static and dynamic contact angles of liquids on various surfaces. It can also measure surface and interfacial tension/energy.

The Contact Angle Measurement System is used to characterize surface wettability. It measures static and dynamic contact angles of liquids on various surfaces. It can also measure surface and interfacial tension/energy.

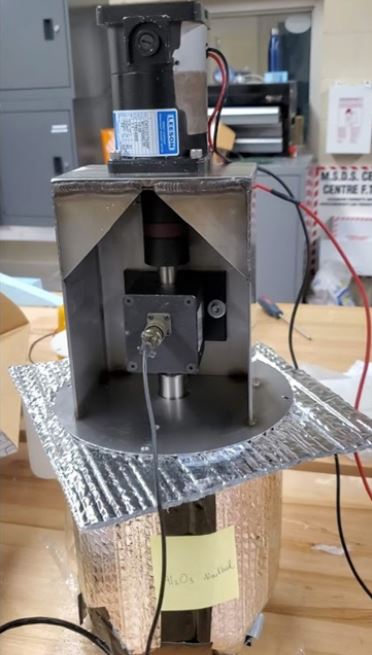

This unit is to study wind-powered heat generation and storage. It allows the testing of kinetic energy conversion to thermal energy through fluid agitation. It uses an electric motor to simulate the kinetic energy input from a wind turbine. Temperature rise in the fluids is measured along with rotational speed and torque through a data acquisition system.

This unit is to study wind-powered heat generation and storage. It allows the testing of kinetic energy conversion to thermal energy through fluid agitation. It uses an electric motor to simulate the kinetic energy input from a wind turbine. Temperature rise in the fluids is measured along with rotational speed and torque through a data acquisition system.

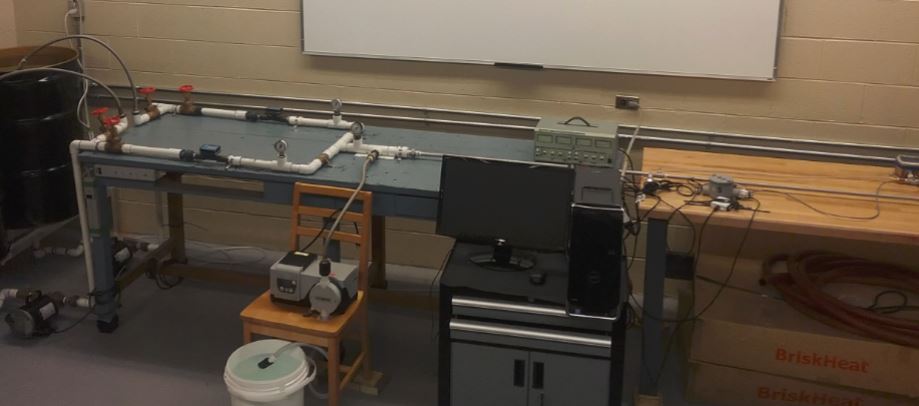

The flow loop is used for pipeline flow drag reduction and oil-water separation research, with flow diagnostic equipment including Laser Doppler Velocimetry (LDV), Particle Imaging Velocimetry (PIV), and high-speed infrared thermometry. With the oil and water tanks and separate flow lines, the setup allows single or two-phase flow experiments. A special diaphragm pump is used to inject concentrated drag reduction polymers or surfactants into the main pipeline. Pressure drop is measured in a 2-m test section by a high-precision differential pressure sensor. The measured pressure drop will be used to calculate flow drag reduction.

The flow loop is used for pipeline flow drag reduction and oil-water separation research, with flow diagnostic equipment including Laser Doppler Velocimetry (LDV), Particle Imaging Velocimetry (PIV), and high-speed infrared thermometry. With the oil and water tanks and separate flow lines, the setup allows single or two-phase flow experiments. A special diaphragm pump is used to inject concentrated drag reduction polymers or surfactants into the main pipeline. Pressure drop is measured in a 2-m test section by a high-precision differential pressure sensor. The measured pressure drop will be used to calculate flow drag reduction.

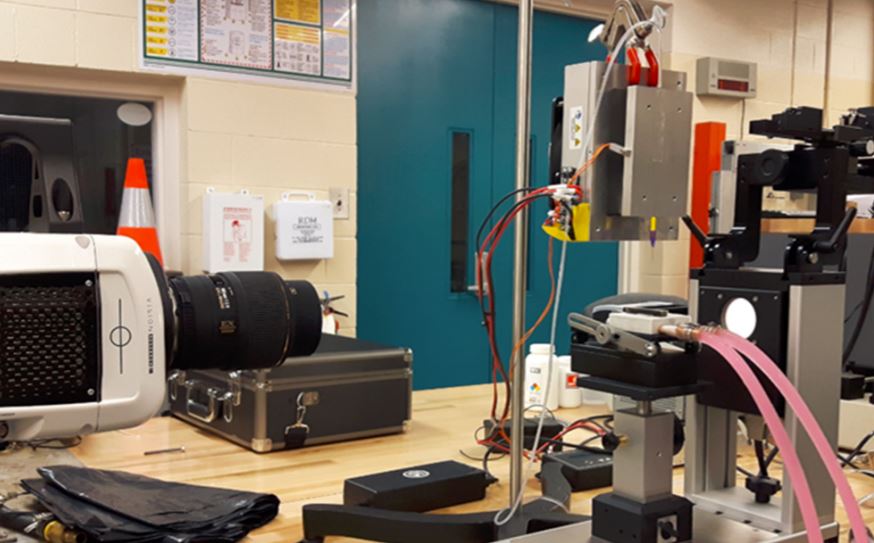

This setup generates small water droplets with controlled temperature. The drops then impact on metal surfaces with variable wettability and controlled surface temperatures to study their impact dynamics, heat transfer and icing behaviours.

This setup generates small water droplets with controlled temperature. The drops then impact on metal surfaces with variable wettability and controlled surface temperatures to study their impact dynamics, heat transfer and icing behaviours.

The high-speed camera is used to capture fluid flow or droplet dynamic images at a high frame rate (up to 10k fps). This enables fluid dynamics analysis at very high temporal and spatial resolutions.

The high-speed camera is used to capture fluid flow or droplet dynamic images at a high frame rate (up to 10k fps). This enables fluid dynamics analysis at very high temporal and spatial resolutions.

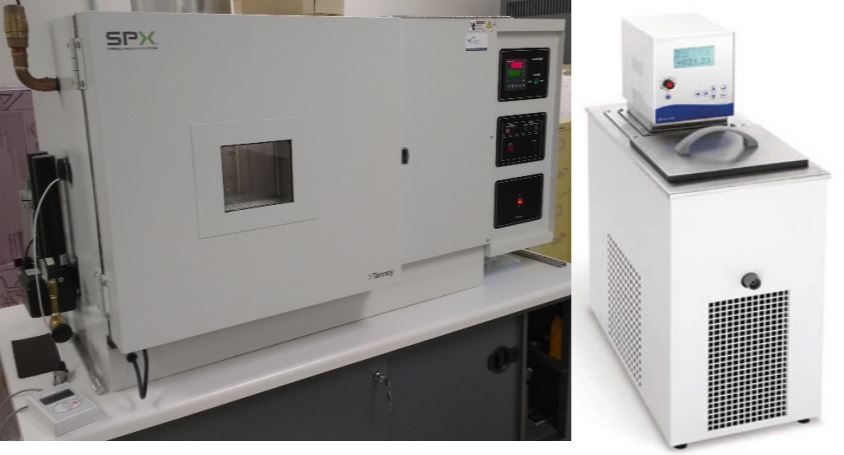

The environment chamber provides a controlled temperature environment for the characterization of materials (such as measuring thermal properties of phase change materials at specified temperatures). The thermal baths provide desired boundary conditions for various heat transfer experiments.

The environment chamber provides a controlled temperature environment for the characterization of materials (such as measuring thermal properties of phase change materials at specified temperatures). The thermal baths provide desired boundary conditions for various heat transfer experiments.

Shared with Dr. Kevin Pope, Dr. Yuri Muzychka, and Dr. Baafour Nyantekyi-Kwakye

Shared with Dr. Yuri Muzychka, Dr. Kevin Pope and Dr. Baafour Nyantekyi-Kwakye

Shared facility in the Faculty of Engineering and Applied Science

Location

EN-1034

Faculty of Engineering and Applied Science

Memorial University of Newfoundland

St. John's. NL